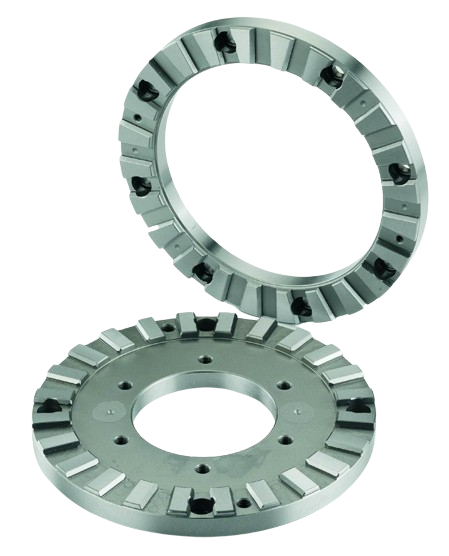

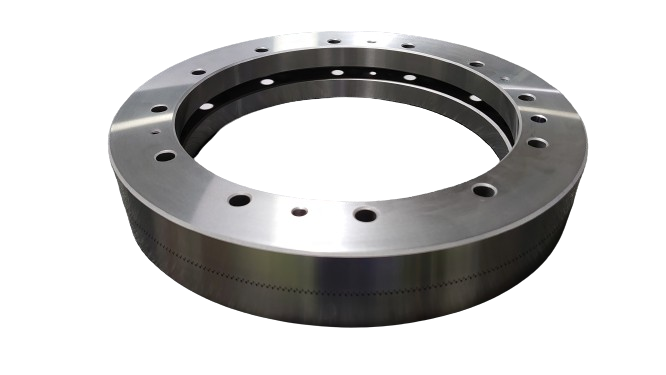

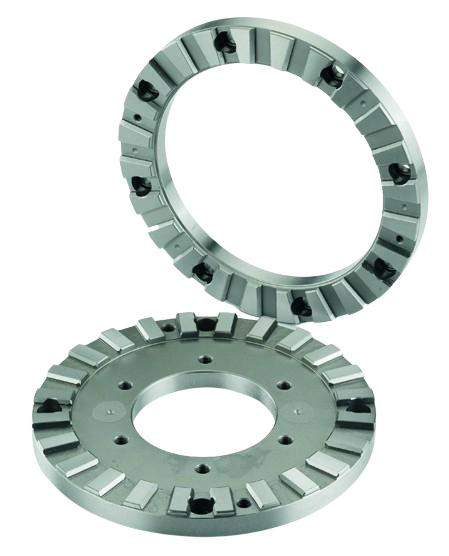

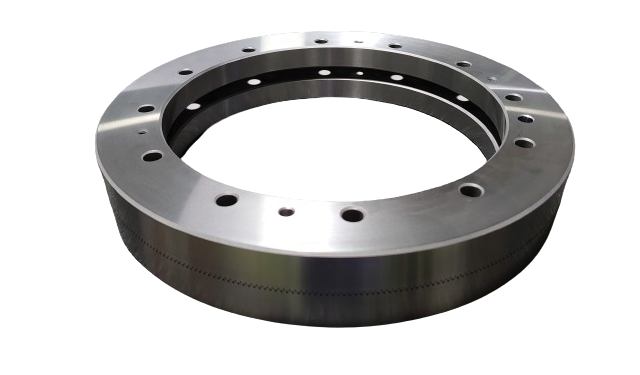

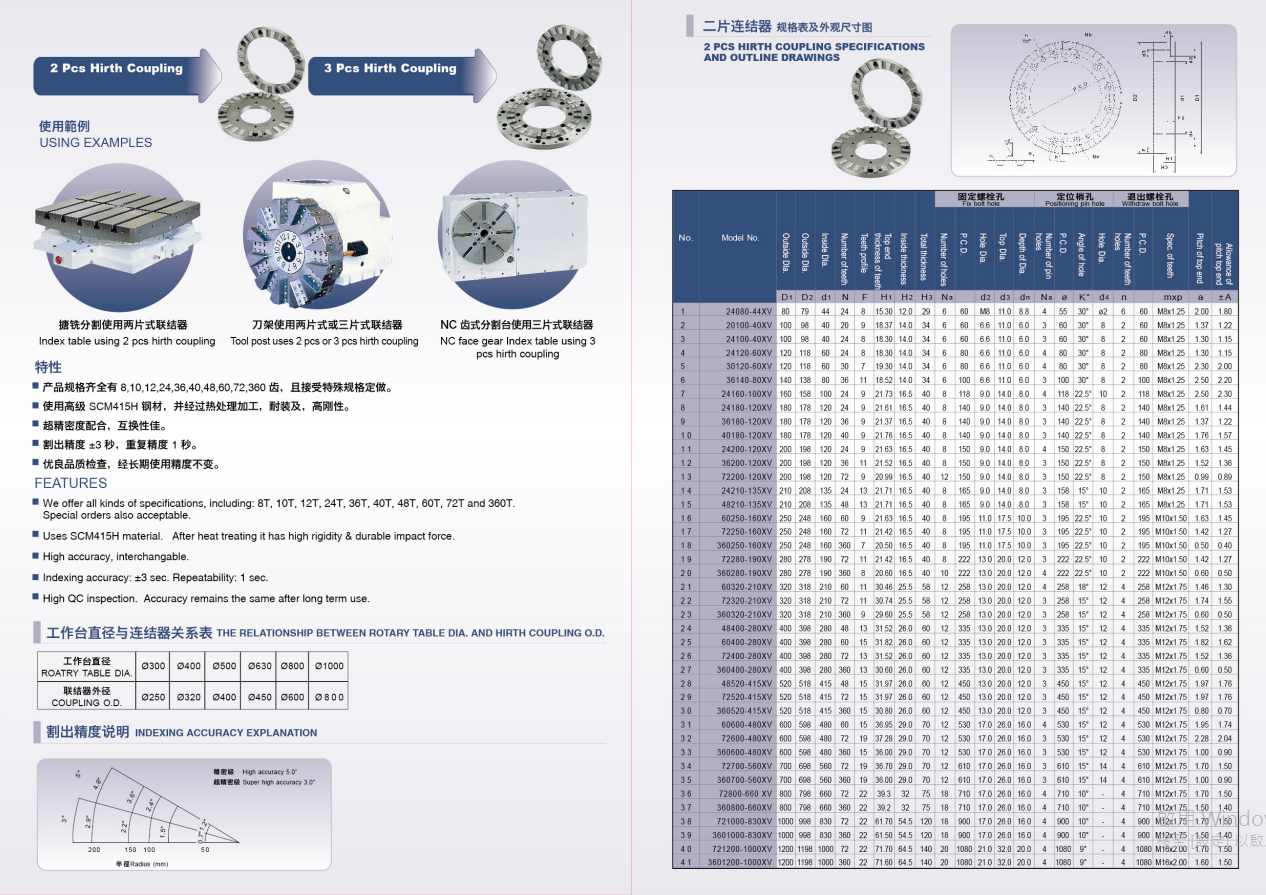

Two-piece Hirth Coupling

All inspections are conducted in a constant temperature inspection room to ensure that each product is inspected and qualified before being shipped to customers. We continuously improve our processes based on inspection data to earn customer trust and grow amidst various challenges.

All inspections are conducted in a constant temperature inspection room to ensure that each product is inspected and qualified before being shipped to customers.

We continuously improve our processes based on inspection data to earn customer trust and grow amidst various challenges.

The catalog is for reference only. For detailed product data and specifications, please contact our company.

The standard materials for Hirth Coupling are SCM-415 (15CrMo) and SCM-440 (42CrMo), which can generally be specified by customers unless there are specific material requirements in the product design.

SCM-415 (15CrMo) is a low-carbon alloy structural steel classified under the green-cross steel category. It is suitable for carburizing heat treatment to improve surface hardness and wear resistance while maintaining toughness in the core. It is commonly used in various special wear-resistant and load-bearing components such as spindles, motor shafts, mechanical parts, and gears.

SCM-440 (42CrMo) is a high-toughness alloy structural steel (medium carbon chromium-molybdenum alloy steel), also known as red-cross steel. It contains chromium (Cr) and molybdenum (Mo) elements and has the advantages of stable composition, low harmful elements, high steel purity, small decarburized layer, and few surface defects. It can undergo tempering heat treatment and high-frequency surface hardening treatment for wear resistance. It is widely used in bolts, shafts, rods, guide pillars, spindle sleeves, gears, and components of engines and machinery that require toughness.

There are many options for the number of teeth in the product, ranging from basic options like 8 teeth, 10 teeth, 12 teeth, 20 teeth, 24 teeth, 40 teeth, 48 teeth, 60 teeth, 72 teeth, and 360 teeth to custom options such as 120 teeth, 144 teeth, 240 teeth, and 720 teeth according to customer requirements. Special tooth numbers not mentioned in the text can also be made to order. When selecting the number of teeth for the workpiece, consideration should be given to how many divisions the actual use requires. When the number of teeth is evenly divisible by the divisions, it means the tooth count can meet these divisions.

It can achieve a cutting accuracy of ±2" and a repeatability positioning accuracy of 1".