Engaged in professional manufacturing of connectors, both standardized and customized

In addition to providing standard specification products

and all products are inspected and certified with an accuracy report.

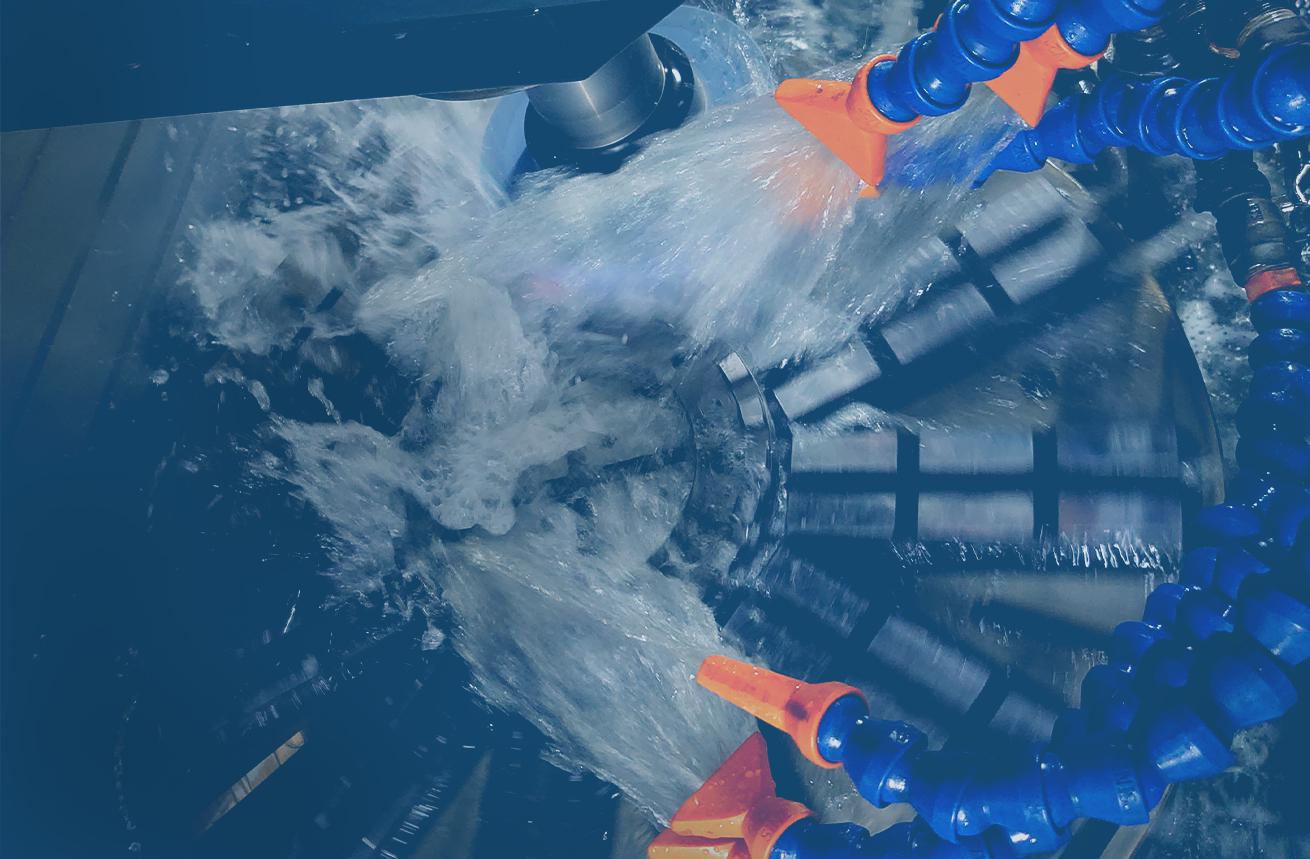

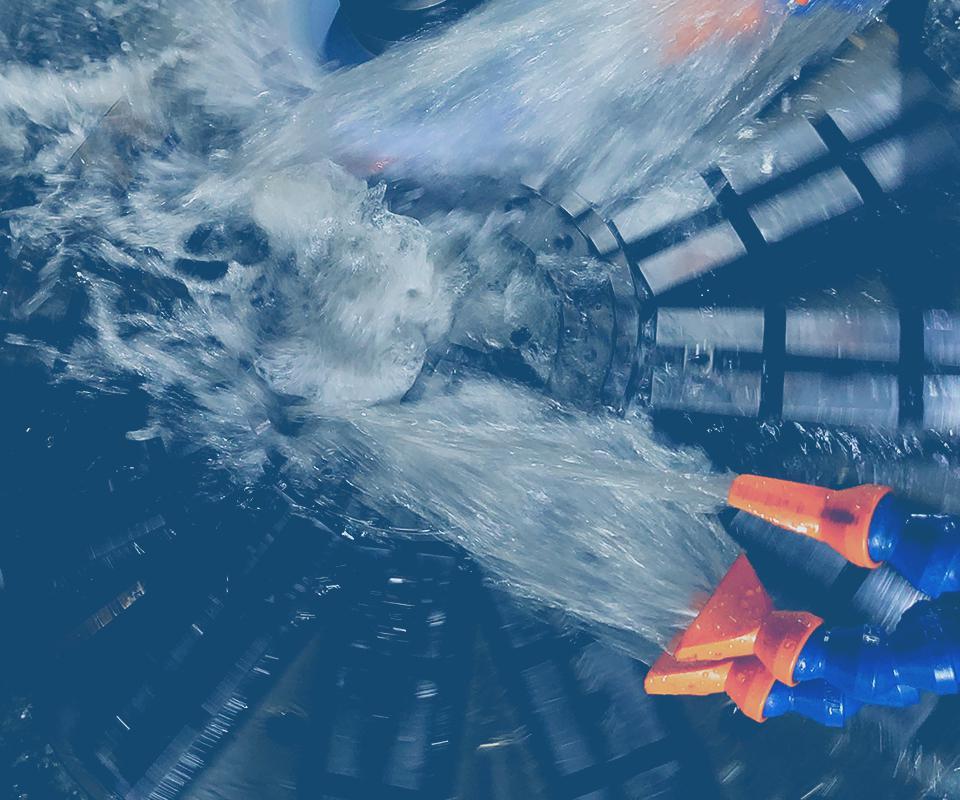

and we have introduced vertical double-spindle internal and external diameter grinding to ensure accuracy.

and we have introduced high-precision Heidenhain encoders to ensure accuracy.

F.E. PRECISION Co., Ltd. was founded in 1994 and engages in professional Manufacturing of connectors, both standardized and customized.

Adhering to the principles of integrity, quality, expertise, and sustainable management, we ensure that every product undergoes quality inspection and comes with an accuracy chart to guarantee the highest standard of quality for each item.

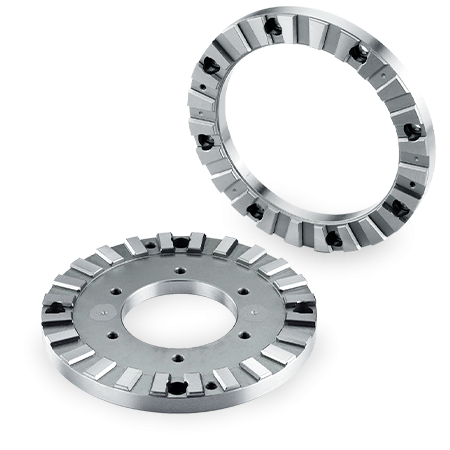

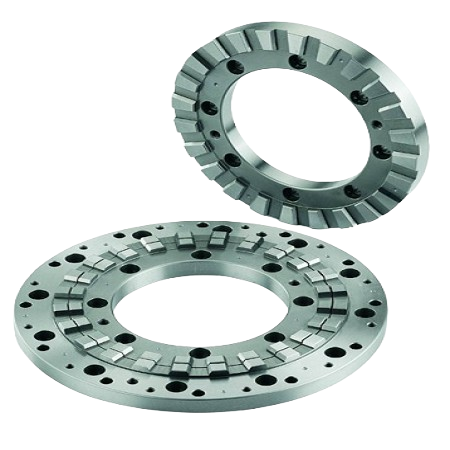

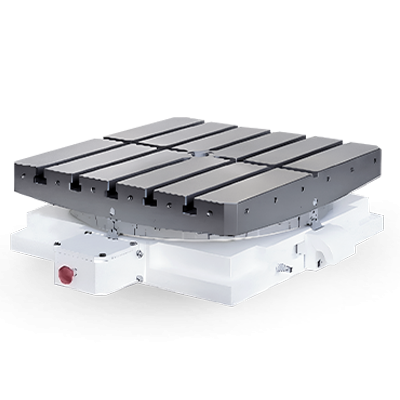

Applied in high-precision intermittent positioning ,

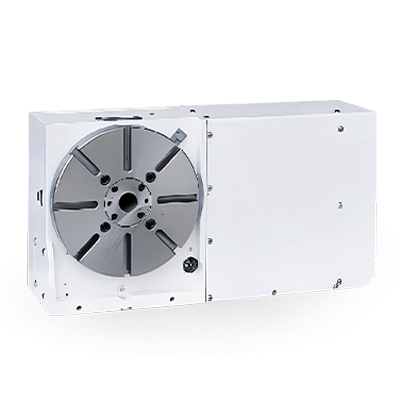

such as rotary tables or surface grinders,

angular heads , vertical spindle grinding heads,

and Hydraulic Turret.

Each product undergoes quality inspection and is accompanied by an accuracy table to ensure that each product has a high level of quality.